EOS2/EOS5

Description

Type overview label printer EOS

One concept, two sizes

The EOS series combines all functions of a solid label printer with highest operating comfort.

EOS2, the compact one

for label roll diameters up to 152 mm

| 1.1 Label printer | EOS2 | |

|---|---|---|

| Printable resolution dpi | 203 | 300 |

| Print speed up to mm/s | 150 | 150 |

| Print width up to mm | 108 | 105.7 |

| Label roll diameter up to mm | 152 | 152 |

| Power supply | 100 – 240 VAC, 50/60 Hz | |

EOS5 for large label rolls

with diameters up to 203 mm

| 1.2 Label printer | EOS5 | |

|---|---|---|

| Printable resolution dpi | 203 | 300 |

| Print speed up to mm/s | 150 | 150 |

| Print width up to mm | 108 | 105.7 |

| Label roll diameter up to mm | 203 | 203 |

| Power supply | 100 – 240 VAC, 50/60 Hz | |

Mobile printing

in production, warehousing or agriculture, wherever labels are required and access to electricity is missing. 24 V input voltage enable the printer to be power supplied by any powerful battery. For technical battery data see accessories

EOS2 mobile

for label roll diameters up to 152 mm

| 1.3 Label printer | EOS2 mobile | |

|---|---|---|

| Printable resolution dpi | 300* | |

| Print speed up to mm/s | 150 | |

| Print width up to mm | 105.7 | |

| Label roll diameter up to mm | 152 | |

| Power supply | 16.5 – 25 VDC | |

*203 dpi on request

EOS5 mobile

for label roll diameters up to 203 mm

| 1.4 Label printer | EOS5 mobile | |

|---|---|---|

| Printable resolution dpi | 300* | |

| Print speed up to mm/s | 150 | |

| Print width up to mm | 105.7 | |

| Label roll diameter up to mm | 203 | |

| Power supply | 16.5 – 25 VDC | |

*203 dpi on request

Details

DR4-25

DR4-25

DR4-50

DR4-50

To achieve accurate imprint with slim materials and ribbons, slim print rollers are needed. These prevent from print roller wear, print head contamination and errors during material feed.

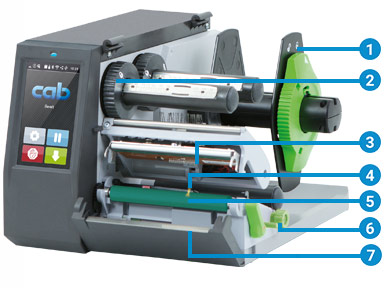

1 Roll holder

The label roll is inserted and automatically centered when closing.

2 Ribbon holder

The stop can be adjusted according to the ribbon width.

3 Print head 203 / 300 dpi

In case of cleaning or wear, the print head can be replaced easily by hand without tools.

4 Label sensor – gap oder reflective

The sensor position can be adjusted via a spindle using the red rotary knob. The chosen position is indicated by a LED.

5 Print roller DR4

In case of cleaning or wear, the print roller can be replaced without tools.

6 Material guide

Using the rotary knob, the guides can be adjusted to the material width

7 Tear-off plate

made of thin sheet steel; jagged, so labels are cleanly separated

Operation panel

Intuitive and easy operation with self-explanatory symbols to configure the device setups

1 LED signal: Power ON

1 LED signal: Power ON

2 Status bar: Data reception, Record data stream, Ribbon pre-warning, SD memory card / USB memory stick, Bluetooth, WLAN, Ethernet, USB slave, Time

3 Printer status: Ready, Pause, Number of printed labels per print job, Label in peel-off position, Awaiting external start signal

4 USB slot for the Service Key or a memory stick, to load data in the IFFS storage

5 Operation:

Cutter / perforation cutter: cutting

Cutter / perforation cutter: cutting

Tear-off mode: print label

Jump to menu

Jump to menu

Reprint last label

Reprint last label

Interrupt and continue print job

Interrupt and continue print job

Stop and delete all print jobs

Stop and delete all print jobs

Label feed

Label feed

External operation panel

providing the same functionality as on the printer

Landscape or portrait mode display

Users are free to choose whether to operate the printer on the external panel or on the one integrated in the device.

Printer connection: USB 2.0 Hi-speed device

1 LED: Power ON

2 USB slot to connect the Service Key or a memory stick, to load data in the IFFS storage

3 Connecting cable USB, lengths of 1.8 m to 16 m Use only specified cables if length succeeds 3 m; for dimensions see assembly instructions

Interfaces on the back of the device

1 for SD memory card

2 2 x USB Host to connect a Service Key, USB memory stick, keyboard, barcode scanner, USB Bluetooth adapter, USB WLAN stick

3 USB 2.0 Hi-Speed Device to connect a PC

4Ethernet 10/100 Mbit/s

5 RS232C 1,200 to 230,400 baud/8 bit

Technical data

| 1.1 | 1.2 | 1.3 | 1.4 | ||||

| Label printer | EOS2 | EOS5 | EOS2 mobile | EOS5 mobile | |||

|---|---|---|---|---|---|---|---|

| Material feed | centered | ||||||

| Printing method: Thermal transfer |  |

|

|

|

|||

| Printing method: Thermal direct |  |

|

|

|

|||

| Printable resolution dpi | 203 | 300 | 203 | 300 | 300 | 300 | |

| Print speed up to mm/s | 150 | 150 | 150 | 150 | 150 | 150 | |

| Print width up to mm | 108 | 105.7 | 108 | 105.7 | 105.7 | 105.7 | |

| Start of printing Distance to locating edge mm | centered | ||||||

| Material 1) | |||||||

| Paper, cardboard, plastics PET, PE, PP, PI, PVC, PU, acrylate, Tyvec |

|

|

|

|

|||

| Shrink tubes ready-for-use |  |

|

– | – | |||

| Shrink tubes continuous, pressed |  |

|

– | – | |||

| Textile tapes |  |

|

|

|

|||

| Packing on rolls, reels |  |

|

|

|

|||

| Packing Fanfold |  |

|

– | – | |||

| Packing Roll diameter up to mm | 152 | 203 | 152 | 203 | |||

| Packing Core diameter mm | 38.1 – 76 | ||||||

| Packing Winding | outside or inside | ||||||

| Labels Width single-lane mm | 10 – 116 | ||||||

| Labels Width multi-lane mm | 5 – 116 | ||||||

| Labels Height excl. label backfeed from mm | 5 | ||||||

| LabelsHeight incl. label backfeed from mm | 12 | ||||||

| Labels Thickness mm | 0.05 – 0.6 | ||||||

| Liner material Width mm | 25 – 120 | ||||||

| Liner material Thickness mm | 0.05 – 0.16 | ||||||

| Continuous material Width mm | 5 – 120 | ||||||

| Continuous material Thickness mm | 0.05 – 0.5 | ||||||

| Continuous material Weight (cardboard) up to g/m2 | 180 | ||||||

| Shrink tubes Width ready-for-use up to mm | 120 | ||||||

| Shrink tubes Width continuous, pressed mm | 5 – 85 | ||||||

| Shrink tubes Thickness up to mm | 1.1 | ||||||

| Ribbon2) Ink side | outside or inside | ||||||

| Ribbon Roll diameter up to mm | 72 | ||||||

| Ribbon Core diameter mm | 25.4 | ||||||

| Ribbon Variable length bup to m | 360 | ||||||

| Ribbon Width mm | 25 –114 | ||||||

| Printer sizes and weights | |||||||

| Width x Height x Depth mm | 253 x 191 x 322 | 264 x 247 x 412 | 253 x 191 x 322 | 264 x 247 x 412 | |||

| Weight kg | 4 | 5 | 4 | 5 | |||

| Label sensor with position indication | |||||||

| Gap sensor for | labels or punch marks and end of material, print marks on transparant materials | ||||||

| Reflective sensor from below or top for | labels and end of material, print marks on non-transparent materials | ||||||

| Distance from center to locating edge centered mm | 0 – 58 | ||||||

| Material passage up to mm | 4 | ||||||

| Electronics | |||||||

| Processor 32 bit clock rate MHz | 800 | ||||||

| Main storage (RAM) MB | 256 | ||||||

| Data storage (IFFS) MB | 50 | ||||||

| Slot for SD memory card (SDHC, SDXC) up to GB | 512 | ||||||

| Battery for time and date, real-time clock |  |

||||||

| Data memory when power is turned off (e.g. serial numbers) |  |

||||||

| Interfaces | |||||||

| RS232C 1,200 to 230,400 baud/8 bit |  |

||||||

| USB 2.0 Hi-speed device to connect a PC |  |

||||||

| Ethernet 10/100 Mbit/s | LPD, RawIP printing, SOAP webservice, OPC UA, WebDAV, DHCP, HTTP/HTTPS, FTP/FTPS, TIME, NTP, Zeroconf, SNMP, SMTP, VNC | ||||||

| 1 x USB host on the operation panel for | Service Key or USB memory stick | ||||||

| 2 x USB host on the back side for | Service Key, USB memory stick, keyboard, barcode scanner, USB Bluetooth adapter, USB WLAN stick, external operation panel | ||||||

| USB WLAN stick 2.4 GHz 802.11b/g/n | hotspot mode or infrastructure mode  |

||||||

| USB WLAN stick 2.4 GHz 802.11b/g/n + 5 GHz 802.11a/n/ac, rod antenna | |||||||

| USB Bluetooth adapter |  |

||||||

| Periphery connection USB host, 24 VDC |  |

||||||

| Operating data | |||||||

| Power supply | 100 – 240 VAC, 50/60 Hz, PFC | 24 VDC | |||||

| Power consumption | Standby 1,8 W / typical 45 W | ||||||

| Temperature / humidity Operation | +5 – 40°C / 10 – 85 %, not condensing | ||||||

| Temperature / humidity Storage | 0-60°C / 20 – 85 %, not condensing | ||||||

| Temperature / humidity Transport | –25 – 60°C / 20 – 85 %, not condensing | ||||||

| Approvals | CE, FCC Class A, ICES-3, cULus, CB, CoC Mexico, CCC, EAC, BIS, BSMI, KC-Mark | ||||||

Accessories

Accessories

-

Print rollers DR4-25, DR4-50

Print roller DR4-25

Material width up to 25 mm; synthetic rubber coating for accurate imprintPrint roller DR4-50

Material width up to 50 mm; synthetic rubber coating for accurate imprint -

External operation panel

providing the same functionality as on the printer

Users are free to choose whether to operate the printer on the external panel or on the one integrated in the device.

Printer connection: USB 2.0 Hi-speed device

Connecting cables are required for power supply. The following or equivalent cables ensure functionality.

Connecting cables USB

Lengths 1.8 to 16 m -

SD memory card

-

USB memory stick

-

USB WLAN stick

2.4 GHz 802.11b/g/n

-

USB WLAN stick

2.4 GHz 802.11b/g/n + 5 GHz a/n/ac

in infrastructure mode with rod antenna for extended reach -

USB Bluetooth adapter

-

Label selection – I/O box

Up to 16 different labels per box can be selected from the memory card by a master control, e.g. PLC. Two boxes can be connected. The I/O box allows simple PLC control processes with four inputs and outputs each via abc programming.

-

Connecting cable RS232 C

9/9 pin, length 3 m

-

Cutter

All printable materials can be cut. The cutter can be pivoted to exchange the material.

Cutter Technical data for EOS2, EOS5 Material Width mm 120 Material Weight cardboard gr/m2 60 – 240 Material Thickness mm 0.05 – 1.1 Cutting length from mm 10 Gap height up to mm 2.5 Cuts/min up to 200 Label winding preferably outside Monitoring Cutter pivoted, final cutter position has not been reached -

Cutter and perforation cutter

Continuous materials such as textiles or shrink tubes are perforated before they are manually separated. In addition, the materials can also be cut. The cutter can be pivoted to exchange the material.

Cutter and perforation cutter Technical data for EOS2, EOS5 Perforating Web distance mm 2.5 Perforating Web width mm 0.8 Material Width mm 45 Material Weight cardboard gr/m2 60 – 240 Material Thickness mm 0.05 – 1.1 Cutting length from mm 10 Gap height up to mm 2.5 Cuts/min up to 200 Label winding preferably outside Monitoring Cutter pivoted, final cutter position has not been reached -

External unwinder

When inserted, the material rolls are automatically centered. The unwinder cannot be installed with EOS mobile.

External unwinder Technical data for EOS2, EOS5 Roll diameter up to mm 390 Core diameter from mm 38 Winding outside or inside Roll weight up to kg 4 -

Brake for fanfold labels

for EOS2 and EOS5. The fanfold material is tightly fed in the printer and printed precisely. The brake cannot be installed with EOS mobile.

-

Battery pack

with a charger unit already included for mobile operation. It is installed under EOS mobile. Per battery capacity, a maximum of 500 print jobs with a label size of 100 x 68 mm and 15 per cent density may be processed.

Battery pack 2 Technical data for EOS2, EOS5 Nominal voltage V 18 Capacity Ah 2.1 Power Wh 36 Charging time approx. h 2 Charging voltage 100 – 240 VAC, 50/60 Hz Dimensions W x H x D mm 221 x 58 x 270 Weight kg 2.5

vergrößern

vergrößern vergrößern

vergrößern vergrößern

vergrößern vergrößern

vergrößern

Reviews

There are no reviews yet.