Label printers SQUIX

Description

They are for use in a wide range of applications. They have been developed with a constant focus on easy and intuitive operation as well as high reliability.

The print mechanics and the chassis are made from high-quality materials and perfectly match in shape and function. A large number of peripherals and software enable customer-specific solutions.

Whether operated stand-alone, linked to a PC or in a network – the rugged printers are always up to the mark. A powerful processor results in print jobs performed quickly and labels provided straight away.

Sample applications

PCB labeling

Type plate labeling

Cardboard and pallet labeling

Label printers with left-aligned material guidance

designed for printing in different print widths on various materials

Slim ones

to print small labels

| 1.1, 1.2 Label printer | SQUIX 2 | |

|---|---|---|

| Printable resolution dpi | 300 | 600 |

| Print speed up to mm/s | 250 | 150 |

| Print width up to mm | 56.9 | 54.1 |

Universal ones

Best-selling industrial device with a wide range of accessories.

| 1.3, 1.4 Label printer | SQUIX 4.3 | SQUIX 4 | ||

|---|---|---|---|---|

| Printable resolution dpi | 203 | 300 | 300 | 600 |

| Print speed up to mm/s | 300 | 300 | 300 | 150 |

| Print width up to mm | 104 | 108.4 | 105.7 | 105.7 |

Basic devices may be provided with an integral cutter.

Wide ones

to print Odette, UCC and GS1 labels in logistics applications

| 1.5, 1.6 Label printer | SQUIX 6.3 | |

|---|---|---|

| Printable resolution dpi | 203 | 300 |

| Print speed up to mm/s | 250 | 250 |

| Print width up to mm | 168 | 162.6 |

Basic device

providing a tear-off plate

They print on labels or on continuous materials wound on rolls or fanfold. Materials are torn off on a jagged plate. Cutting is an option, so is external rewinding.

Peel-off device

providing a rewinder internally

Peeling off labels is a feature added to a basic version. Labels are separated from the liner after printing to be removed by hand or by an applicator.

The extra wide one

to print pallet or barrel labels

<tr”></tr”>

| Label printer | A8+ |

|---|---|

| Printable resolution dpi | 300 |

| Print speed up to mm/s | 150 |

| Print width up to mm | 216 |

Details

Label printer with left-aligned material guidance

- Label printer SQUIX 4 P,

peel-off device providing a rewinder internally

as a peel-off device providing a rewinder internally

1 Hinged cover

Material stock can be checked and entire printing processes followed through a large panoramic window.

2 Plungers

One is fixed on the inside. To get a good print image, the second one is moved to the outside margin of a label.

3 Rugged metal chassis

made of cast aluminum to assemble all the units

4 Coated print rollers

Synthetic rubber is a standard to get highly accurate print images. Silicone coating is an option for extra long service life.

5 Peel-off function

to separate labels from the liner. A powered guide roller and a pinch roller enable highly accurate imprint and peel-off.

6 Peripheral port

to plug additional modules easily and quickly. They are screw-fixed.

7 Ribbon holder

Ribbons are quick and easy to replace using three-part tightening axles.

8 Roll holder

Constant tension by means of the margin stop (spring-mounted, screw-capped) while material is fed

9 Internal rewinder

to wind labels or liners with or without a cardboard core on peel-off devices. Materials are easy to handle using a three-part tightening axle.

10 Rocker

Suspension and Teflon-made guide rollers reduce traction and improve the accuracy of print images.

11 Material guide

assembled to the rocker. By a user turning the rotary knob, the stop moves to the margin of a label.

Print image accuracy

The smaller a label, the higher are the demands. Using slip correction, print offset can be reduced by ±0.2 mm.

Operation panel

Self-explanatory symbols help with the device settings and enable a printer to be operated intuitive and easily.

1 LED: Power ON

1 LED: Power ON

2 Status bar: reception of data, record data stream, pre-warning to a ribbon ending, SD memory card / USB memory stick plugged, Bluetooth, WLAN, Ethernet, USB slave, time

3 Printer status: ready, pause, number of labels printed in a print job, label in peel-off position, external start signal awaited

4USB port to plug a service key or a memory stick, to transfer data to the IFFS memory

5 Operation

Cutter / perforation cutter: cutting

Cutter / perforation cutter: cutting

External rewinder: wound outside or inside

Tear-off mode / peel-off mode: printing a label

Applicator: printing and labeling in individual steps

Jump to menu

Jump to menu

Reprint last label

Reprint last label

Interrupt and continue print job

Interrupt and continue print job

Stop and delete all print jobs

Stop and delete all print jobs

Label feed

Label feed

vergrößern

vergrößernSetup options

vergrößern

vergrößernPrinting parameters

vergrößern

vergrößernPrint position Y

vergrößern

vergrößernPrint speed selection

vergrößern

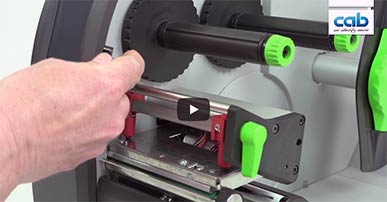

vergrößernVideo tutorials

External operation panel

same functionality as on the printer

display in landscape or portrait mode

Users are free to choose whether to operate the external panel or the one installed on the printer.

USB 2.0 Hi-Speed device to connect a printer

1 LED: Power ON

2 USB port to plug a service key or a memory stick, to transfer data to the IFFS memory

3 Connecting USB cable, lengths 1.8 m to 16 m. If length succeeds 3 m, use only specified cables. For dimensions see assembly instructions

Print heads

A print head can be replaced by any other one, provided they are of equal width. They are detected and calibrated by the CPU automatically.

Major data such as the operational performance, maximum operational temperatures and heat energies are kept in memory on a print head. The data can be read at the premise.

Print heads provided for SQUIX 2, SQUIX 4 – 300, 600 dpi

to print sharp-edge images

to print small fonts and graphics on typeplates

to print on materials that imply high energy needs

Print heads provided for SQUIX 4.3, SQUIX 6.3 – 203, 300 dpi

durable

to operate in harsh environments, thermal direct printing

Maintenance

Label sensors

unlock by touch to be pulled out.

Print heads

require few steps to be replaced. In general, no adjustments are needed.

Print rollers

are quick and easy to remove using a screw.

ONE tool

is provided ready on a device to replace all the components and assemble periphery.

Technical data

| 1.1 | 1.2 | 1.3 | ||||||

| Label printer | SQUIX 2 | SQUIX 4.3 | SQUIX 4 | SQUIX 6.3 | ||||

|---|---|---|---|---|---|---|---|---|

| Material feed | Left-aligned | |||||||

| Printing method: Thermal transfer |  |

|

|

|

|

|

|

|

| Printing method: Thermal direct |  |

– |  |

|

|

– |  |

|

| Printable resolution dpi | 300 | 600 | 203 | 300 | 300 | 600 | 203 | 300 |

| Print speed up to mm/s | 250 | 150 | 300 | 300 | 300 | 150 | 250 | 250 |

| Print width up to mm | 56.9 | 54.1 | 104 | 108.4 | 105.7 | 105.7 | 168 | 162.6 |

| Start of printing: Distance to locating edge mm | 2 | 2.8 | 1.2 | 2 | 0.5 | 3.2 | ||

| Material1) | ||||||||

| Paper, cardboard, plastics PET, PE, PP, PI, PVC, PU, acrylate, Tyvec |  |

|

|

|||||

| Shrink tubes ready-for-use | – |  |

|

|||||

| Packing on rolls, fanfold |  |

|

|

|||||

| Packing Roll diameter up to mm | 205 | |||||||

| Packing Core diameter mm | 38.1 – 76 | |||||||

| Packing Winding | outside or inside | |||||||

| Labels Width mm | 4 – 63 | 20 – 116 | 46 – 176 | |||||

| Labels Height excl. label backfeed2) from mm | 4 | 4 | 6 | |||||

| Labels Height incl. label backfeed2) from mm | 4 | 6 | 12 | |||||

| Labels height incl. label backfeed / peel-off from mm | 6 | 6 | 12 | |||||

| Labels Thickness mm | 0.03-0.6 | |||||||

| Liner material Width mm | 24 -67 | 24 – 120 | 50 – 180 | |||||

| Liner material Thickness mm | 0.03-0.16 | |||||||

| Continuous material Width mm | 24 – 67 | 24 – 120 | 50 – 180 | |||||

| Continuous material Thickness mm | 0.05-0.5 | |||||||

| Continuous material Weight (cardboard) up to g/m2 | 300 | |||||||

| Shrink tubes Width ready-for-use up to mm | – | 120 | – | |||||

| Shrink tubes Thickness up to mm | – | 1.1 | – | |||||

| Ribbon3) Ink side | outside or inside | |||||||

| Ribbon Roll diameter up to mm | 90 | |||||||

| Ribbon Core diameter mm | 25.4 | |||||||

| Ribbon Variable length up to m | 600 | |||||||

| Ribbon Width mm | 25 – 67 | 25 – 114 | 50 – 170 | |||||

| Internal rewinder in peel-off version | ||||||||

| Outside diameter up to mm | 142 | |||||||

| Core diameter mm | 40 | |||||||

| Winding | outside | |||||||

| Printer sizes and weights | ||||||||

| Width x Height x Depth mm | 200 x 288 x 460 | 252 x 288 x 460 | 312 x 288 x 460 | |||||

| Weight kg | 9 | 10 | 14 | |||||

| Label sensor indicating the position | ||||||||

| Gap sensor for | labels or punch marks and end of material, print marks on transparant materials | |||||||

| Reflective sensor reflex from below or top for | labels and end of material, print marks on non-transparent materials | |||||||

| Distance of sensor to locating edge left-aligned mm | 5 – 26 | 5 – 60 | 5 – 60 | |||||

| Material passage up to mm | 2 | |||||||

| Electronics | ||||||||

| Processor 32 bit clock rate MHz | 800 | |||||||

| Main storage (RAM) MB | 256 | |||||||

| Data storage (IFFS) MB | 50 | |||||||

| Slot for SD memory card (SDHC, SDXC) up to GB | 512 | |||||||

| Battery for time and date, real-time clock |  |

|||||||

| Data memory when power is switched off (e.g. serial numbering) |  |

|||||||

| Interfaces | ||||||||

| RS232C 1,200 to 230,400 baud/8 bit |  |

|||||||

| USB 2.0 Hi-Speed device to connect a PC |  |

|||||||

| Ethernet 10/100 Mbit/s | LPD, RawIP printing, SOAP webservice, OPC UA, WebDAV, DHCP, HTTP/HTTPS, FTP/FTPS, TIME, NTP, Zeroconf, SNMP, SMTP, VNC | |||||||

| 1 USB host on the operation panel to plug a | service key, USB memory stick, USB WLAN stick, USB Bluetooth adapter | |||||||

| 2 USB hosts on the back of the device to plug a | keyboard, barcode scanner, USB memory stick, USB WLAN stick, USB WLAN stick with a rod antenna, USB Bluetooth adapter, an external operation panel | |||||||

| USB host, 24 VDC, to plug peripherals |  |

|||||||

| Digital I/O interface providing 8 inputs and outputs |  |

|||||||

| Operating data | ||||||||

| Power supply | 100 – 240 VAC, 50/60 Hz, PFC | |||||||

| Power consumption | Standby <10 W / typical 100 W | |||||||

| Temperature / humidity: Operation | +5 – 40°C / 10 – 85% not condensing | |||||||

| Temperature / humidity: Storage | 0 – 60°C / 20 – 85% not condensing | |||||||

| Temperature / humidity Transport | –25 – 60°C / 20 – 85% not condensing | |||||||

| Approvals | CE, FCC Class A, ICES-3, cULus, CB, CoC Mexico, CCC, EAC, BIS, BSMI, KC-Mark | |||||||

Technical data SQUIX with SQUIX M and SQUIX MP by comparison (PDF)

Accessories

Videos

ideo: Label printers SQUIX – designed for industrial application

Powered by YouTube. See all cab videos: cab Channel auf YouTube.

Other formats: Label printer SQUIX – designed for industrial application (MPEG-4; 218 MB)

SQUIX case studies

Formula Student: SQUIX dynamically imprints names on acetate silk

Read case study

20 years united by wine labeling: Vier Jahreszeiten winegrowers and cab

Read case study

cab Video Tutorials SQUIX

SQUIX Dispensing version: Rewind labels internally

SQUIX Dispensing version: Remove internally wound labels

SQUIX Dispensing version: Dispensing labels

SQUIX Dispensing version : Changing dispense plate

SQUIX: Install WLAN stick

Documentation

3D CAD models

The files are provided in STEP format, which requires CAD software. Follow this link to download a free STP Viewer:

VariCAD Viewer (External website). For downloading the CAD models you need to register. cab will handle your personal information as described in our Privacy statement. This information will not be accessible to any third party for marketing purposes. This category is under construction, more models to follow.

vergrößern

vergrößern vergrößern

vergrößern vergrößern

vergrößern vergrößern

vergrößern Play

Play Play

Play Play

Play Play

Play Play

Play Play

Play Play

Play Play

Play Play

Play Play

Play Play

Play Play

Play Play

Play

Reviews

There are no reviews yet.