Description

Automatic labeling

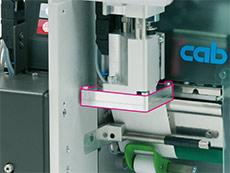

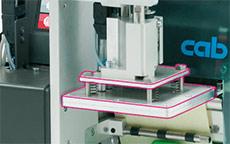

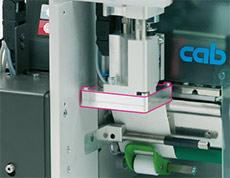

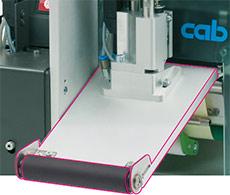

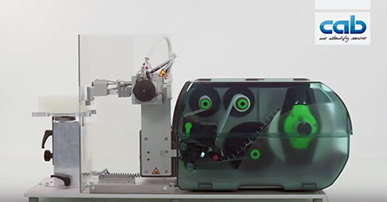

SQ 1000 is a further development of the proven S1000 applicator, fully compatible, adding extra functions. Existing applications can continue without limitations. In conjunction with a SQUIX printer, the SQ 1000 is a cost-effective solution for semi-automatic labeling tasks. Labels are applied onto items by means of a stroke cylinder.

Easy to configure

The applicator can be fully set on the printer control panel, configurations be stored and called up. Automatic calibration features speed up the setup.

Process control

Detailed statistical values are provided, so are sophisticated error messages. Constant control enables response right away in events of errors.

Updates

Applicator firmware can be updated on the printer control panel or the printer‘s web server. New features and specific solutions can therefore be tested right away and distributed in the field.

| Applicator | SQ 1000 – 220 |

SQ 1000 – 300 |

SQ 1000 – 400 |

SQ 1000 – 520 |

|---|---|---|---|---|

| Operated with | SQUIX 2, SQUIX 4.3, SQUIX 4, SQUIX 4.3 M, SQUIX 4 M, SQUIX 6.3 | |||

| Cylinder strokemm | 220 | 300 | 400 | 520 |

| Stroke of a pad as calculated below a unitmm | 64 | 144 | 244 | 364 |

| Weight packaging excludedkg | 4.5 | 5 | 5.5 | 6.0 |

| Consumption of powerW max. | 15 | |||

| Compressed airbar | 4.5 | |||

| Cycle rateca.1) | 25 labels/min | |||

1) calculated at a stroke of 100 mm below a unit, using labels 100 mm high and a print speed of 100 mm/s

Play

Play

Reviews

There are no reviews yet.