Description

The MACH 4S provide all features of an industrial printer with a wide application range. The print mechanics and the chassis are made of high-quality materials and perfectly match in terms of shape and function.

The large, colored touchdisplay with self-explanatory symbols offers best operability. Labels and ribbons are easy to insert from the front. The centered material guide eliminates any need of adjustments.

The hightech electronic board integrates all the needed interfaces as standard and is ready for any connection.

Sample applications

PCB labels

When only little space is available – smallest label size 5 x 5 mm

Type plates

Pin sharp fonts, graphics and barcodes up to 600 dpi

Cardboard box and pallet labels

up to a passage width of 120 mm

Material guide

Material guide

centered

Type B with tear-off edge

for printing on all materials that are wound on rolls or reels or fanfold.

| 1.1 Label printer |

MACH 4.3S |

MACH 4S |

| Printable resolutiondpi |

203 |

300 |

300 |

600 |

| Print speedup to mm/s |

300 |

300 |

300 |

150 |

| Print width up to mm |

104 |

108.4 |

105.7 |

105.7 |

Type P with peel-off function

for printing on all materials that are wound on rolls or reels or fanfold. In addition, the labels can be dispensed.

| 1.2 Label printer |

MACH 4.3S |

MACH 4S |

| Printable resolutiondpi |

203 |

300 |

300 |

600 |

| Print speedup to mm/s |

300 |

300 |

300 |

150 |

| Print widthup to mm |

104 |

108.4 |

105.7 |

105.7 |

| Label heightfrom mm |

12 |

Type C with cutter

for printing on all materials that are wound on rolls or reels or fanfold. From 12 mm in height, the labels and continuous materials can be cut.

| 1.3 Label printer |

MACH 4.3S |

MACH 4S |

| Printable resolutiondpi |

203 |

300 |

300 |

600 |

| Print speedup to mm/s |

300 |

300 |

300 |

150 |

| Print widthup to mm |

104 |

108.4 |

105.7 |

105.7 |

| Cutting lengthfrom mm |

12 |

| Gap heightup to mm |

2.5 |

| Cuts/min, without materialup to |

100 |

| Stop print job when |

final cutter position has not been reached |

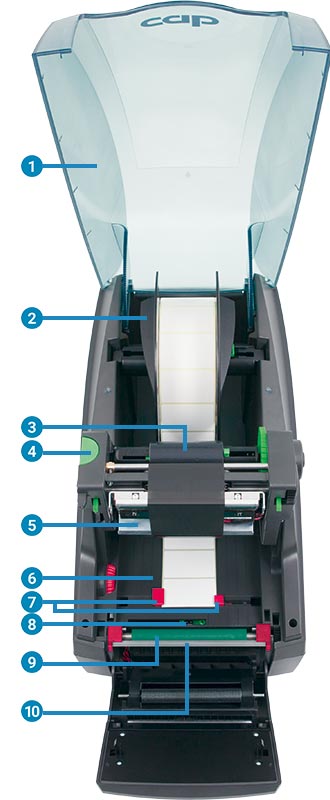

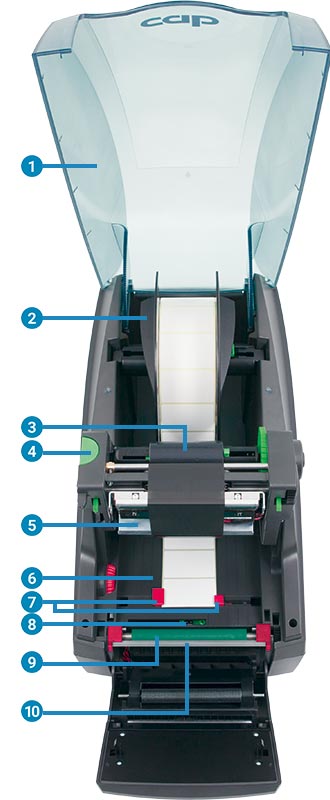

Details

1 Cover with a large panoramic window

It can be opened wide. The integrated damping mechanism provides smooth closing. Label stock is visible at any time.

2 Roll holder

The label roll is put onto the holder and, at this, is automatically centered. Materials of different widths can be placed within the box.

3 Ribbon holder

The ribbon is pushed onto the spring-mounted holder and is centered by means of a margin stop and the position indication. The insertion in the print mechanics is simple and comfortable.

4 Print mechanics

It opens at the push of a button and offers easy access.

5 Print heads

All print heads are freely interchangeable. They are automatically detected and calibrated by the CPU. Major data sucha s running performance, maximum operating temperature and heat energy are directly stored in the print head. The data can be read at the plant.

6Gap sensor

It is arranged for labels or punch marks and end of material as well as for print marks in a centered position. In case of multi-track labels, you can switch to a sensor that is shifted 10 mm to the left.

7 Material guide

With the lateral retaining wheel the width is adjusted. At this, the labels are centered.

8 Reflective sensor

Labels and end of material as well as print marks are identified by the slideable sensor.

9 Print roller DR4

It can be quickly and easily unlocked in few steps for cleaning or replacement. Coating: synthetic rubber

DR4-M25

DR4-M50

DR4-M80

To achieve accurate imprint with slim materials and ribbons slim print rollers are needed. These prevent from print roller wear, print head contamination and errors during material feed.

10 Peel-off function (with “P” type)

The liner tape is lead down behind the operation panel. The label separates from the liner tape on the peel-off edge. In terms of application safety, label peel-off has to be tested.

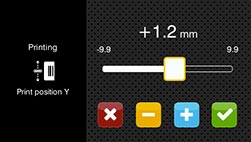

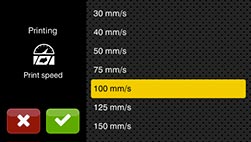

Operation panel

Operation panel

Intuitive and easy operation with self-explanatory symbols to configure the device setups

1 LED signal: Power ON

2 Status bar: Data reception, Record data stream, Ribbon pre-warning, SD memory card / USB memory stick plugged in, WLAN, Ethernet, USB Slave, Time

3 Printer status: Ready, Pause, Number of printed labels per print job, Label in peel-off position, Awaiting external start signal

4 Operation

Cutter cutting a material

Cutter cutting a material

Tear-off mode / peel-off mode: print a label

Applicator: print and apply labels in individual steps

Tear-off mode: label backfeed

Tear-off mode: label backfeed

Jump to menu

Jump to menu

Stop and delete all print jobs

Stop and delete all print jobs

Reprint

Reprint

Label feed

Label feed

Suspend and continue a print job

Suspend and continue a print job

External operation panel

If the operation panel of a printer cannot be accessed, an additional external one can be plugged.

Same functionality as on the printer

Landscape or portrait mode

Operability as desired on the external operation panel or on the printer

Printer connectivity: USB 2.0 Hi-Speed device

1 LED: Power ON

2 USB slot to plug a service key or a memory stick, to transfer data to the IFFS memory

3 Connecting USB cable for power supply cab provides specified cables. Lengths are 1.8 m to 16 m.

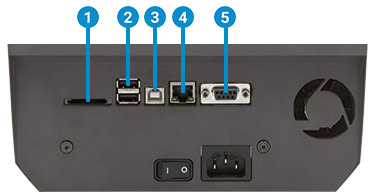

Interfaces on the back of the device

1 for a SD memory card

2 2 x USB host to connect a Service Key, USB memory stick, keyboard, barcode scanner, USB WLAN stick

WLAN hotspot or infrastructure mode: In hotspot mode it is possible to directly connect a mobile device with the printer via WLAN.

3 USB 2.0 Hi-speed device to connect a PC

4 Ethernet 10/100 Mbit/s

5 RS232C 1,200 to 230,400 baud/8 bit

Material guide

Material guide

Operation panel

Operation panel Cutter cutting a material

Cutter cutting a material Tear-off mode: label backfeed

Tear-off mode: label backfeed Jump to menu

Jump to menu Stop and delete all print jobs

Stop and delete all print jobs Reprint

Reprint Label feed

Label feed Suspend and continue a print job

Suspend and continue a print job vergrößern

vergrößern vergrößern

vergrößern vergrößern

vergrößern vergrößern

vergrößern vergrößern

vergrößern

Reviews

There are no reviews yet.