Description

Laser marking system XENO 3 / XENO 3+

to mark metal and plastic plates permanently

|

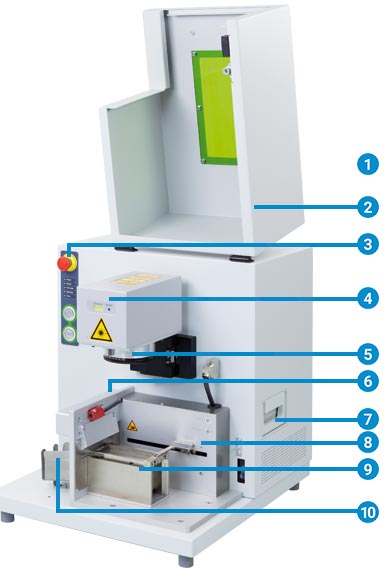

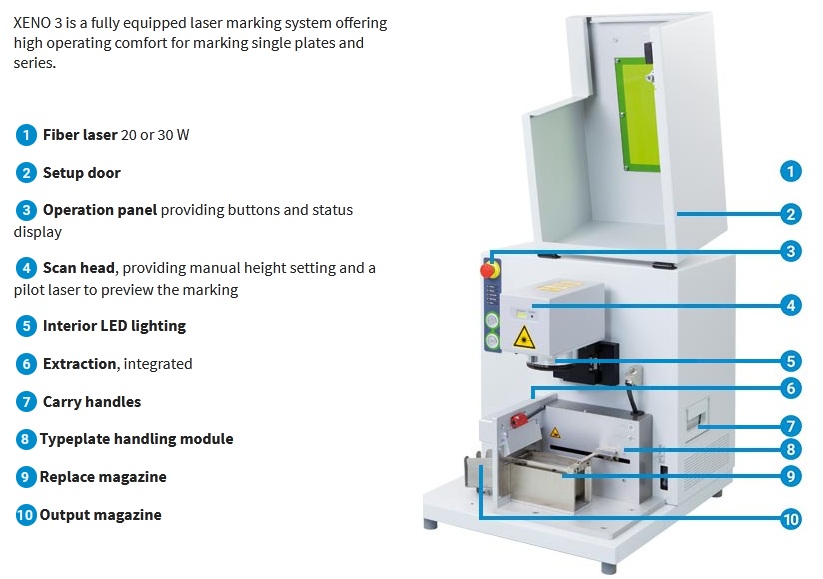

XENO 3 provides an integrated laser system to mark metal and plastic plates permanently. Fiber laser beam source, control unit and operation room are incorporated in a joint laser safety housing according to protection class 1. Due to its compact design and small footprint, XENO 3 fits with desktop operations. Galvanometer scanner from SCANLAB “Made in Germany”. The XENO 3+ variant has a laser beam source from IPG “Made in Germany” and an extended warranty of 2 + 2 years. Markings applied by a XENO 3 remain clearly legible even in the long term in rough surroundings. |

Hydraulic cylinders, engines, pumps, gears, vehicle chassis oder system components are typical items to be marked with a XENO 3.

Replace magazines enable to process different plate sizes. Plates to be processed are 40 x 20 to 120 x 100 mm in size, resp. 0.5 to 1 mm in thickness. Plate stacking is possible to heights of 50 mm.

The marking can be observed through the protection window and with the help of the lit interior. Fold-out carry handles simplify the installation of the system.

With the comprehensive cabLase marking software layouts are graphically designed, markings controlled and processes monitored.

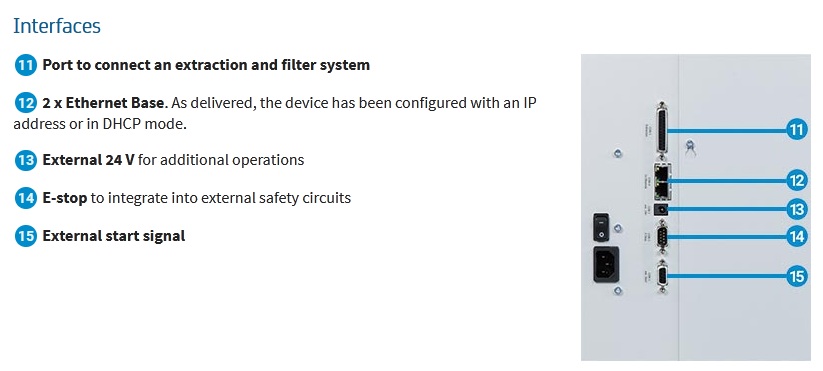

The system might be remote controlled or monitored in networks in which machines interact with other machines or human beings.

XENO 3 is particularly suitable of metal engravings and ablation of top layer.

Video: XENO 3 Typeplate Laser Marking SystemWe show features and benefits |

Reviews

There are no reviews yet.