Label dispensers HS and VS

- Description

- Details

- SPECIFICATIONS

- LABEL SPECIFICATIONS

- echnical data

- Accessories

- Videos

- Documentation

- Reviews (0)

Description

Easy operation and precise label dispensing for a great price

Every label size can be dispensed easily using the HS and VS dispenser. The labels can be stamped or cut without any space inbetween.

You can use any outside shape whether cornered or round. Transparent material can also be dispensed.

Two dispensing directions

Two versions are available so as to ensure that the labels can be removed properly for every use.

vergrößernHS Horizontal dispensing direction

vergrößernHS Horizontal dispensing direction

for label rolls with bottom leading print image

for label rolls with bottom leading print image

Peel off the label upwards from its bottom edge and stick it to the product.

vergrößernVS Vertical dispensing direction

vergrößernVS Vertical dispensing direction

for label rolls with top leading

for label rolls with top leading

print image

Peel off the label forward from its upper edge and stick it to the product from the shortest distance possible. Particularly suitable for larger labels as the adhesive side is already directed to the product.

Two operation panels

Basic version

Label feed

- automatically after removal of the label

With operation panel

Label counter from 0 – 9,999

Label feed

- slow / fast

- after pressing the push button or

- automatically after removal of the label or

- by an external signal on the rear side of device

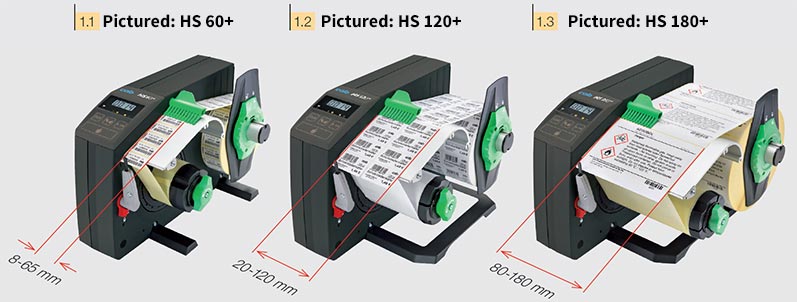

Three widths of material for HS and VS

Details

1 Operation panel

Use the operation panel to select various operating modes. This allows setting the feed supply rate to either “slow” or “fast”. Labels are fed automatically after removal, by pressing a control key or upon an external signal. A counter indicates how many labels have already been removed.

2 Label sensor

For round labels, the sensor will be set to the label’s A apex. You can adjust the pre-dispense height B to between 4 and 18 mm.

3 Label brake

This puts the base material under tension so as to ensure that the labels will be dispensed safely. It can be swivelled away easily when the material is changed.

4 Liner rewinder

Simply insert and clamp the backing tape immediately behind the peel-off edge. It is wound up completely by the strong motor.

5 Roll holder

The label rolls are guided by the stable roll retainer.

SPECIFICATIONS

| Print Method: | Thermal inkjet; Dye & Pigment ink |

| Print Resolution: | Up to 1200 x 4800 dpi |

| Print Speeds: | Draft Mode: 4.5” (114mm) per second Normal Mode: 1.8” (46mm) per second High Quality Mode: 0.8” (20mm) per second |

| Print Head: | Replaceable Multi-Use Print Head |

| Ink: | Separate Cyan, Magenta and Yellow Ink Tanks, Process Black |

| Colors: | 16.7 million |

| Color Matching: | ICC color profiles for all Primera-supplied media. Ability to add custom ICC color profiles for other media types. |

| Print Width: | 0.5″ (13mm) to 8.25″ (210mm) |

| Media Width: | 1.5″ (38mm) to 8.375″ (212mm) |

| Media Types: | Roll-fed pressure-sensitive labels, roll-fed tags, fan-fold labels or tag |

| Media Sensing: | Moveable see-through sensor for die-cut labels; reflective sensor for labels and tags with black stripe; can use continuous and pre-printed labels and tags |

| Supply Roll: | 6″ (152mm) maximum diameter on 3″ (76mm) core. |

| Ink Level Warning: | Calculates actual number of prints remaining based upon ink usage of graphics being printed (patent-pending) |

| Indicator Lights: | Power, Pause, Ink |

| Controls: | Pause, Load/Feed, Unload |

| Operating Systems: | Windows 7/8/10+ (Coming Soon – MacOS 10.11+) |

| Data Interface: | USB 2.0 and Wired Ethernet |

| Label Design Software: | Seagull Scientific Bartender® UltraLite Software version included; can also be used with most other popular label design & graphics programs |

| Electrical Rating: | 12VDC, 5.0A |

| Power Requirements: | 100-240VAC, 50/60 Hz, 60 watts |

| Certifications: | UL, UL-C, CE, FCC Class A |

| California Prop 65: | |

| Weight: | 36.5 lbs. (16.6 kg) |

| Dimensions: | 17.25″W x 9.1″H x 17.25″D (438mmW x 231mmH x 438mmD) |

| Included: |

Bartender Ultralite software for Windows, non-perforated 4”X3” Extreme White Gloss Polyester starter roll, print head and CMY ink tanks |

LABEL SPECIFICATIONS

| Max | Min | |

| Label width: | 8.25″ (209mm) | 0.5″ (13mm) |

| Liner/media width: | 8.375″ (212mm) | 1.5″ (38mm) |

| Label height/length: | 24″ (609mm) | 0.5″ (13mm) |

| Gap between labels: | 10″ (254mm) | 0.1″ (2.5mm) |

| Width of thru-hole opening: | 0.5″ (13mm) | 0.25″ (6mm) |

| Gap Sensor Adjustment Range: | 1.9″ (48mm) | 0.2″ (5mm) |

| Reflective/Black Mark Width*: | N/A | 0.1″ (2.5mm) |

| Max Outer Diameter (OD): | 6″(152mm) | N/A |

| Inner Core Diameter (ID): | 3″ (76mm) | 3″ (76mm) |

| Total Thickness (Liner + Label)**: | 0.010” (10 mil) | N/A |

| Distance from edge of media to edge of label: | Printer driver assumes 2 mm gap. However, this is adjustable via the left margin offset. | |

* The Reflective/Black Mark should be opaque to infrared light. The mark should be between the labels. The end of the mark should correspond with the beginning of the label.

** This is the recommended maximum. There are two factors that determine whether the printer will accept any particular stock thickness.

echnical data

| Common technical data | HS | VS | with operation panel “+” | |

|---|---|---|---|---|

| Dispensing direction | horizontal | vertical | ||

| Label orientation – print image | bottom leading | top leading | ||

| Labels | on rolls, standard or die cut, fan-folded optional | |||

| Materials | paper, textiles, plastics also transparent | |||

| Feed supply rate up to mm/sec | 200 | 100 / 200 | ||

| Label roll: outside diameter up to mm | 200 | |||

| Label roll: core diameter mm | 38 – 76 | |||

| Label roll: weight max. kg | 4 | |||

| Label roll: winding direction | outside or inside | |||

| Rewinder | ||||

| Liner outside diameter up to mm | 155 | |||

| Label sensor | ||||

| Scanning | leading edge of label | |||

| Distance to leading edge mm A mm | 5 – 55 | |||

| Pre-dispense: B mm | 4 – 18 | |||

| Operation panel | ||||

| Device indicator “ON” | green LED | LED and label counter “ON” | ||

| Device indicator Error | red LED | Label counter, flashing | ||

| Selector switch: label feed automatic or on demand | – |  |

||

| Control button with label feed on demand | – |  |

||

| Selector switch feed supply rate | – | slow / fast | ||

| LCD display label counter | – | 0 – 9999 | ||

| Control button reset label counter | – |  |

||

| Display dispensing via external signal | – |  |

||

| Connections | ||||

| Peripheral connection for peel-off on demand via external signal | – |  |

||

| Inlet connector for non-heating apparatus | Power supply | |||

| Power switch | On / Off | |||

| Operating data | HS and VS | mobile | |

| Power supply | 100 – 240 V ~ 50/60 Hz | 16,5 – 25 VDC | |

| Power consumption operation / stand by | max. 30 W / 5 W | ||

| Temperature / humidity: operation | +5 – 40°C / 10 – 85% non-condensing | ||

| Temperature / humidity: storage | +0 – 60°C / 20 – 80% non-condensing | ||

| Temperature / humidity: transport | – 25 – 60°C / 20 – 80% non-condensing | ||

| Noise level | < 60 dB | ||

| Approvals | CE, FCC Class A, ICES-3, cULus | ||

| Device specific dimensions | HS60 and VS60 | HS120 and VS120 | HS180+ and VS180+ |

| Width of labels including liner mm mm | 8 – 65 | 20 – 120 | 80 – 180 |

| Height of labels one-wide mm | 5 – 300 | 8 – 600 | 20 – 600 |

| Height of labels multi-wide mm | 5 – 110 | 8 – 110 | 20 – 110 |

| Device dimensions | |||

| Height x depth without material mm | 250 x 360 | 250 x 360 | 250 x 360 |

| Width mm | 180 | 230 | 300 |

| Weight kg | 3,3 | 3,6 | 4,0 |

Accessories

-

Battery pack HS/VS 120

To allow mobile labelling at every place where you do not have any socket outlet for power supply.

HS and VS allow dispensing more than 5,000 labels using a single battery charge.

-

Brake for fanfold labels

The brake is used to tightly guide and precisely print fanfold material.

Videos

Video: Label dispenser HS and VS

Powered by YouTube. See all cab videos: cab Channel auf YouTube.

Documentation

3D CAD models

The files are provided in STEP format, which requires CAD software. Follow this link to download a free STP Viewer:

VariCAD Viewer (External website). For downloading the CAD models you need to register. cab will handle your personal information as described in our Privacy statement. This information will not be accessible to any third party for marketing purposes. This category is under construction, more models to follow.

Reviews

There are no reviews yet.